One of our esteemed customers in the automotive industry has contacted us for a new project. This time, they were developing a new generation part for electric cars and needed a partner to verify its functionality, validate the design, and perform accelerated lifetime tests. They had additional requirements, including testing multiple devices in parallel and logging to a central database.

This was not our first project with this customer. In previous projects, we have implemented a flexible TestStand framework that provided a predefined TestStand configuration, customized database scheme, and LabVIEW drivers. The LabVIEW drivers were made for communication with the device under test, climate chambers and database, drivers for alarming and logging. We also had a library of template sequences for product-specific tests.

For the new project, we just had to create a new project specific source code control repository, link the flexible TestStand framework, and import the database scheme. We were then ready to start with project-specific implementation.

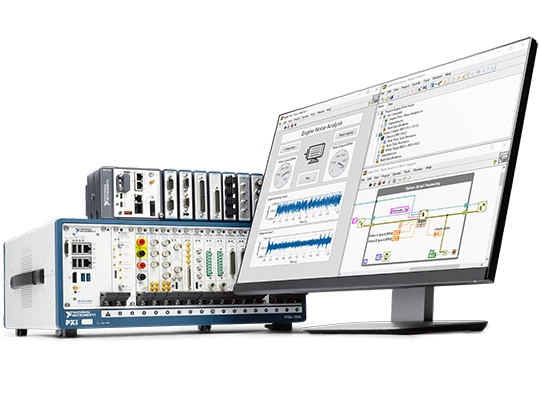

The test hardware consisted of 3 identical PXI racks. With its advanced architecture and standardized components, PXI enabled faster test development. Plus, with the ability to integrate multiple instruments into a single chassis, PXI offered unparalleled flexibility and scalability.

To meet the customer's requirements for parallel testing, we implemented a dedicated application that could run on their PXI racks. We were able to achieve a 95-5 ratio of parallel to sequential testing, thanks to the modular design of the PXI system, Object-Oriented programming, and advanced synchronization options in TestStand.

We added a Microsoft windows-based workstation to the setup that runs the central database and executes the TestStand sequences. With the TestStand Batch model, we could split the execution into 9 sockets - one for each device under test. We adjusted the batch model of TestStand so we could divide these 9 sockets over the 3 PXI racks, enabling us to connect 9 devices to the PXI racks and address them all from the 9 sockets in TestStand.

In the end, we were able to meet nearly all the requirements of the project, and our customer was delighted with the results. Our flexible TestStand framework made it easy to adapt to their changing needs, and we were able to deliver a solution that exceeded their expectations. We're excited to continue helping our customers in the automotive industry with their testing needs and look forward to delivering even more successful projects in the future.