Test setups are tools developed to evaluate and characterize new products. When these products become successful, it is necessary to enhance their efficiency or improve their specifications over time. This often requires an upgrade to the test setup's specifications and requirements. Keeping the setup up-to-date and equipped to handle the demands of these products is essential to maintain their widespread recognition and acceptance.

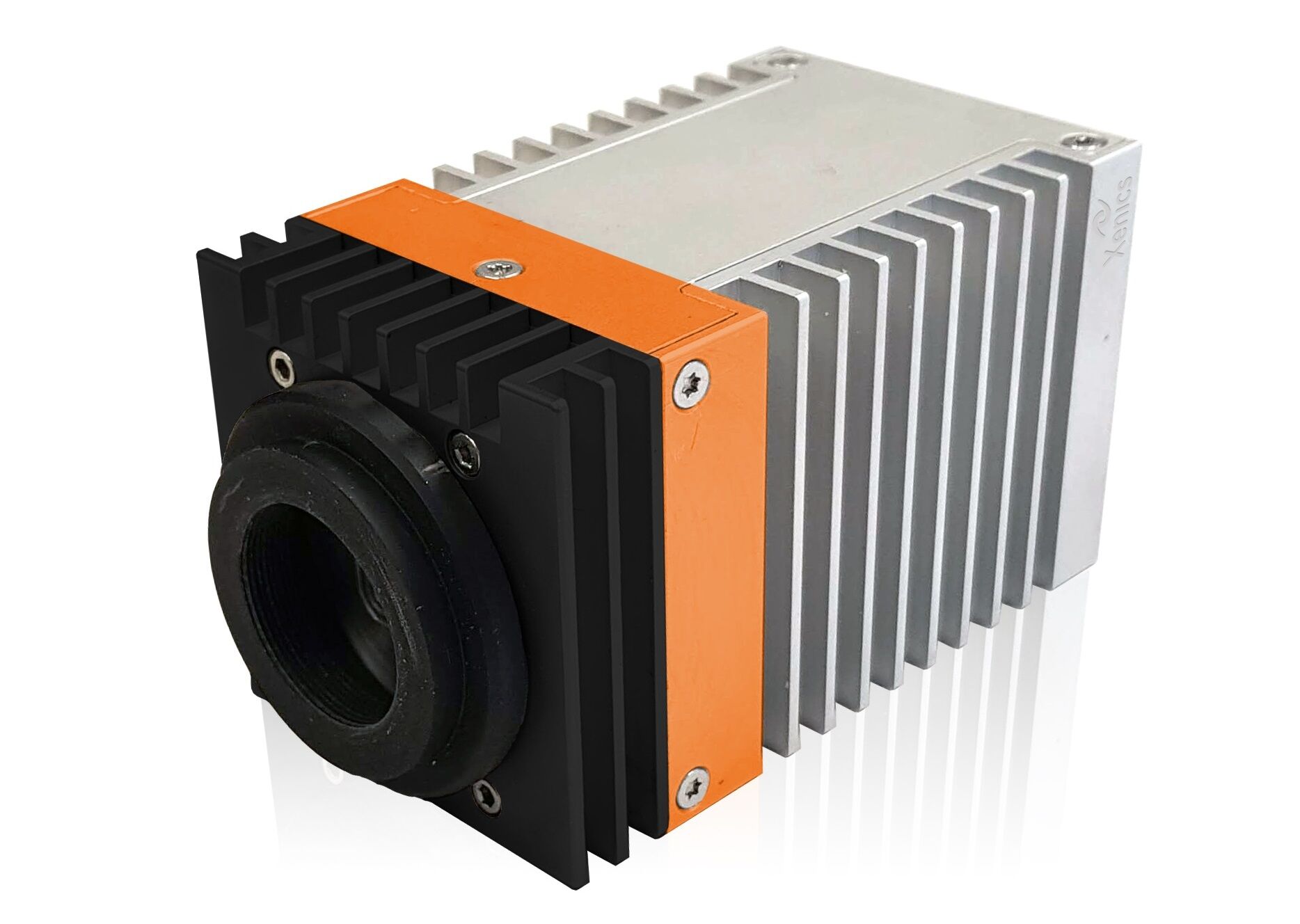

Xenics approached us with a challenge to upgrade their test setup. It was time to upgrade the setup's specifications to match the advancements in the specifications of their camera chips. Xenics, founded in Belgium in 2000, is a designer and manufacturer of infrared sensors, cores, and cameras. The company has maintained its expertise in SWIR imaging technology and expanded its portfolio to include LWIR solutions for various markets. The test setup at Xenics is used by R&D engineers and serves as a platform for single die- and flip-chip testing (where an InGaAs layer is bonded to the chip before testing).

The original test setup was equipped with NI PXI hardware, which was acquired in 2012 and operated using LabVIEW and LabWindows CVI Sofware. In 2021, the hardware was upgraded to a modern, high-performance PXI system that includes a Windows controller and supports LabVIEW, TestStand, and Python. The goal was to create a flexible framework that would give R&D engineers maximum control over the hardware. A Python interface was also required to retain compatibility with existing Python code. A comprehensive overview of available hardware, software specifications, and customer requirements was provided at the beginning of the project, followed by the creation of a design document outlining the necessary hardware and software modules to meet the specifications.

When a new chip is developed at Xenics, the test setup is used to characterize and test the product. The upgraded PXI hardware and accompanying software streamline the testing process and improve the accuracy of characterization results. The Python interface provides an easy-to-use interface for engineers, making it easier to run tests and analyze results.

The abstraction of the PXI hardware is based on functionality, including standard analog and digital signal processing, advanced timing structures, and capturing analog values for image acquisition. An SPI interface was also included. Each PXI card has its own abstraction. Python interaction is facilitated through the TestStand interface. The integration between TestStand and LabVIEW allows for the automated processes to run in TestStand while allowing Test Engineers to adjust and monitor low-level steps in LabVIEW. When running the TestStand sequence, one can observe the executed LabVIEW code simultaneously in LabVIEW.

The upgrade to the PXI hardware and accompanying software is a success for Xenics. The improved efficiency of their testing process provides more accurate results, helping them stay at the forefront of their industry.