Not all projects start with clear specifications. Projects that start from an idea, most likely lead to very high-tech research projects, just like this one.

One of our OEM-clients had an idea for one of their next generation machines. The project started with very limited specifications and in the end, we are contributing to high-tech measurements in their industry.

VI Technologies was asked to join forces with Settels-Savenije group of companies (www.sttls.nl), a company that has expertise in development of precision parts and advanced systems. The combination of knowledge in developing advanced dynamic/physics systems and the software expertise of VI Technologies, led to a state-of-the-art measurement and control system which is used in the early development of the next generation machines.

The joint development team transformed the initial idea into a plan. Milestones were defined and research and development started in an agile influenced way. In 3 week sprints, the project was evaluated and adjusted where needed.

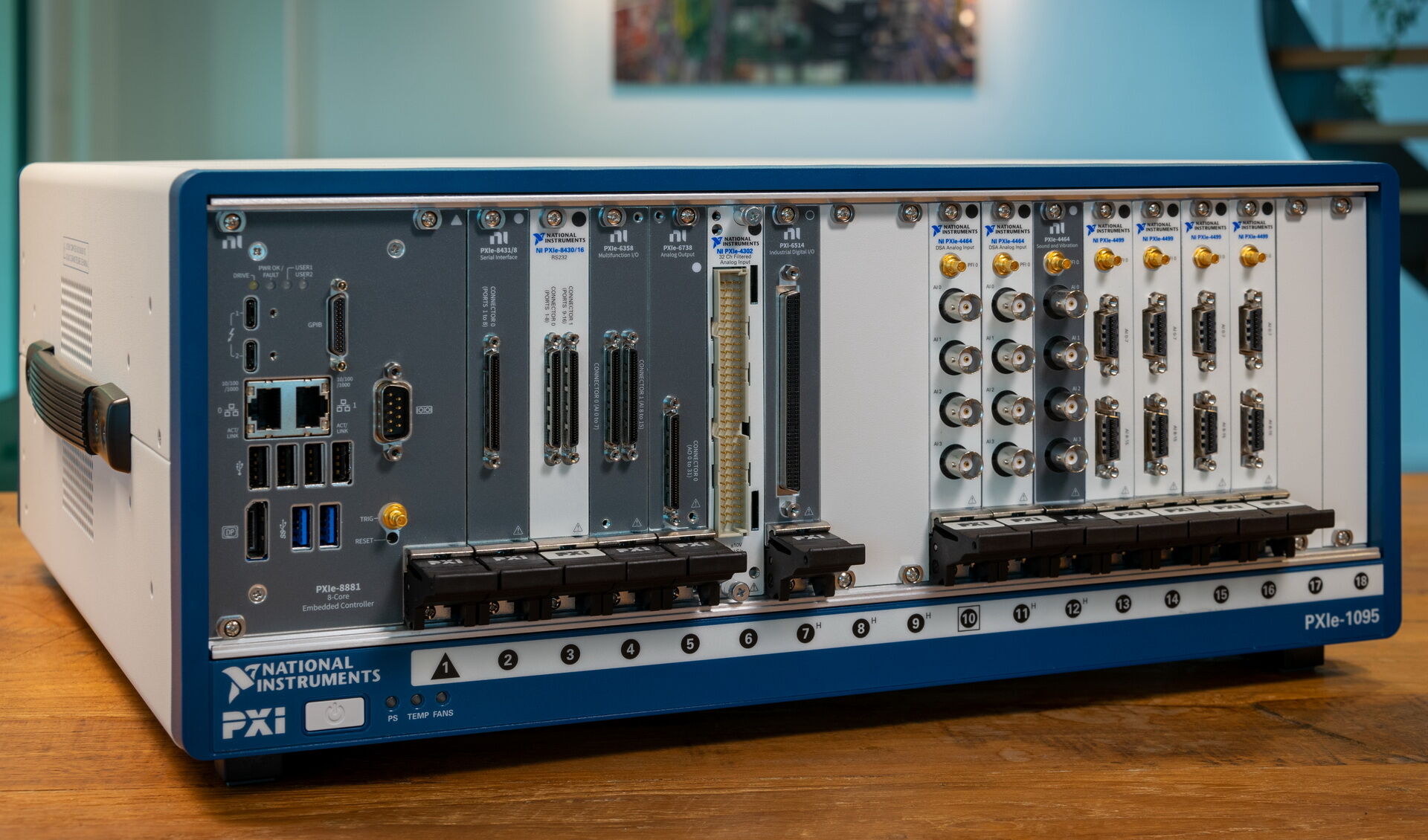

At the start, it became clear that the project asked for a modular and scalable design, ease of use, configurable sensors and signals, on the fly processing, and displaying of measurements… All these requirements point to a PXI system. A PXI system can be configured depending on the used measurement and control cards. Different cards can be used. From a simple multipurpose IO card to a very specific sound and vibration measurement card. Thanks to the modular design of the PXI hardware and the use of GOOP (Graphical Object-Oriented Programming), the team was able to create a configurable measurement system with GUI on the PXI system. Check our blog if you want to know more about GUI’s on a PXI system.

This measurement system was used in the early testing and validation of the project. The results of these tests defined the further development and milestones of the project.

Based on the first results, it was clear that some level of control was needed for this setup. Valves, temperature controllers, etc need to be controlled from the PXI system during the measurements and experiments. Thanks to the modular design the PXI system, it was very easy to add control cards. And thanks to the modular and scalable software design, these functions could be added to the software as well.

The results of this measurement and control setup were shared with the end customer. They were pleasantly surprised with these results and decided to start using this setup in other projects. At this moment not 1, but 3 of these systems are used and maintained.